Introduction

Semiconductors are the backbone of modern technology, powering everything from smartphones and laptops to automobiles, medical devices, and defense systems. As the global demand for semiconductors rises, countries worldwide are investing heavily in domestic chip manufacturing to reduce reliance on imports and strengthen their supply chains.

India, recognizing the strategic importance of semiconductors, launched the India Semiconductor Mission (ISM) in December 2021 as part of the “Make in India” and “Atmanirbhar Bharat (Self-Reliant India)” initiatives. This mission aims to develop a sustainable semiconductor and display manufacturing ecosystem in India, reducing dependence on imports and positioning the country as a global semiconductor hub.

This blog explores the objectives, key initiatives, investment plans, challenges, and future prospects of the India Semiconductor Mission.

What is the India Semiconductor Mission (ISM)?

The India Semiconductor Mission (ISM) is a government-led initiative designed to build a robust semiconductor and display fabrication (fab) ecosystem in India. The mission is implemented by the Ministry of Electronics and Information Technology (MeitY) under the Semicon India Programme, with a total budget of ₹76,000 crore ($10 billion).

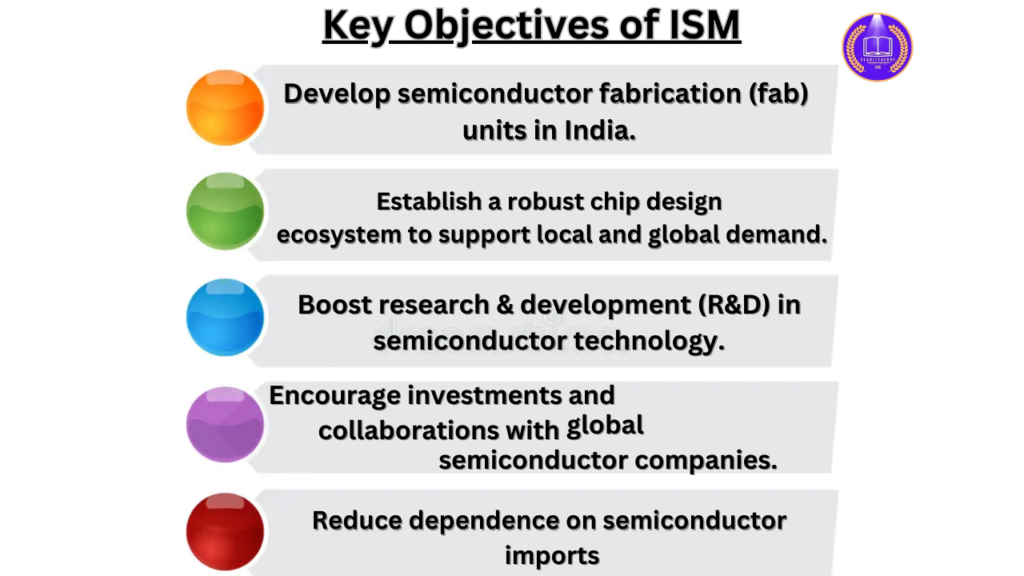

Key Objectives of ISM

- Develop semiconductor fabrication (fab) units in India.

- Establish a robust chip design ecosystem to support local and global demand.

- Boost research & development (R&D) in semiconductor technology.

- Encourage investments and collaborations with global semiconductor companies.

- Reduce dependence on semiconductor imports, strengthening India’s supply chain.

Vision of ISM

- Position India as a global semiconductor manufacturing hub.

- Enhance India’s role in the global electronics supply chain.

- Foster innovation, job creation, and economic growth through semiconductor manufacturing.

Why Does India Need a Semiconductor Mission?

1. Rising Global Demand for Semiconductors

- The global semiconductor market is expected to reach $1 trillion by 2030.

- Industries like automotive, telecommunications, consumer electronics, and defense heavily rely on semiconductors.

2. Heavy Dependence on Imports

- India imports over 90% of its semiconductor requirements from countries like China, Taiwan, and South Korea.

- The global chip shortage during COVID-19 disrupted India’s industries, leading to production delays in automobiles and electronics.

3. Strengthening India’s Digital Economy

- India is the world’s second-largest mobile phone manufacturer.

- The demand for 5G networks, AI, IoT, and smart devices is growing rapidly.

- A strong domestic semiconductor industry will support India’s digital transformation.

4. National Security & Strategic Importance

- Semiconductor self-sufficiency is crucial for defense, cybersecurity, and critical infrastructure.

- Countries like the USA, China, South Korea, and Japan are investing billions in their semiconductor industries.

Key Initiatives Under the India Semiconductor Mission

The ISM has introduced several programs and incentives to attract investments and develop the semiconductor ecosystem in India.

Semicon India Programme (₹76,000 Crore Incentive Package)

The Indian government has allocated ₹76,000 crore ($10 billion) to boost semiconductor manufacturing and research. This includes:

Incentive for Semiconductor Fabrication Units (₹67,000 crore)

- The government will provide up to 50% financial assistance to companies setting up semiconductor fabs in India.

- Aims to attract leading global semiconductor firms.

Design Linked Incentive (DLI) Scheme (₹1,500 crore)

- Supports startups and firms involved in chip design.

- Encourages local semiconductor design and R&D.

Incentive for Display Manufacturing (₹12,000 crore)

- Focuses on OLED, AMOLED, and MicroLED display fabrication.

- Aims to reduce India’s dependency on China and South Korea for display technology.

Electronics Manufacturing Cluster (EMC) Scheme

- Establishes semiconductor clusters with state-of-the-art infrastructure.

- Key locations include Tamil Nadu, Gujarat, Karnataka, and Uttar Pradesh.

Major Semiconductor Projects in India

Several global and domestic firms have expressed interest or committed investments under ISM:

1. Tata Group’s Semiconductor Fab in India

- Tata Electronics is planning to establish a semiconductor manufacturing unit in India.

- The Tata Group is in talks with Taiwanese and Japanese semiconductor firms for collaborations.

2. Vedanta-Foxconn Semiconductor Joint Venture

- In 2022, Vedanta Ltd. and Foxconn announced a $19.5 billion investment to set up a semiconductor and display fab in Gujarat.

- Focuses on manufacturing 28nm and 65nm semiconductor chips.

3. ISMC Semiconductor Plant in Karnataka

- International Semiconductor Consortium (ISMC) announced a $3 billion investment in Karnataka.

- Plans to set up a 65nm foundry to serve India’s growing semiconductor needs.

4. Tower Semiconductor Collaboration with India

- Tower Semiconductor (Israel) has shown interest in setting up a chip manufacturing facility in India.

Challenges Facing India’s Semiconductor Mission

While ISM is a step in the right direction, India faces several challenges in establishing a robust semiconductor industry.

1. Lack of Existing Infrastructure

- Setting up semiconductor fabs requires billions in investment and highly specialized infrastructure.

- India currently lacks high-tech semiconductor fabrication facilities.

2. Shortage of Skilled Workforce

- Semiconductor manufacturing requires highly skilled engineers, researchers, and technicians.

- India needs specialized training programs to develop a semiconductor-ready workforce.

3. Global Competition & Supply Chain Dependencies

- India is competing with China, Taiwan, the USA, and South Korea, which have well-established semiconductor industries.

- Key raw materials like silicon wafers, rare earth metals, and photolithography equipment are imported.

4. High Initial Costs & Long Gestation Period

- Setting up a semiconductor fab requires 5-7 years and billions of dollars in investment.

- Companies must overcome long development timelines and financial risks.

Future of India’s Semiconductor Industry

Despite these challenges, India’s semiconductor mission holds huge potential. The government is taking proactive steps to make India a global semiconductor hub.

1. Strengthening Global Partnerships

- India is partnering with Taiwan, Japan, USA, and European nations to bring semiconductor expertise and investment.

2. Building Semiconductor Research & Training Centers

- Indian universities are launching semiconductor design and manufacturing programs.

- Collaboration with global institutions for R&D in advanced chip technology.

3. Expansion of Domestic Electronics Manufacturing

- With a growing smartphone, automobile, and IoT industry, India will require more domestic chip manufacturing.

4. Focus on Advanced Semiconductor Technologies

- Investment in AI-driven chip design, 5G chipsets, and quantum computing semiconductors.

Conclusion

The India Semiconductor Mission (ISM) is a transformational initiative that has the potential to make India a global leader in semiconductor manufacturing. With strong government support, international collaborations, and growing domestic demand, India is on the path to reducing chip dependency on imports and becoming a key player in the global semiconductor supply chain.