About Farm Mechanisation in India

Farm mechanisation simply means using machines and modern tools instead of doing all farm work by hand or with animals. It helps farmers do their work faster, more easily, and on time—like sowing seeds, watering crops, or harvesting. In a country like India, where many people still depend on farming for their income, using machines can really improve crop production, reduce hard manual labour, and save time. Mechanisation also helps farmers deal with labour shortages and grow more food efficiently.

Current Scenario

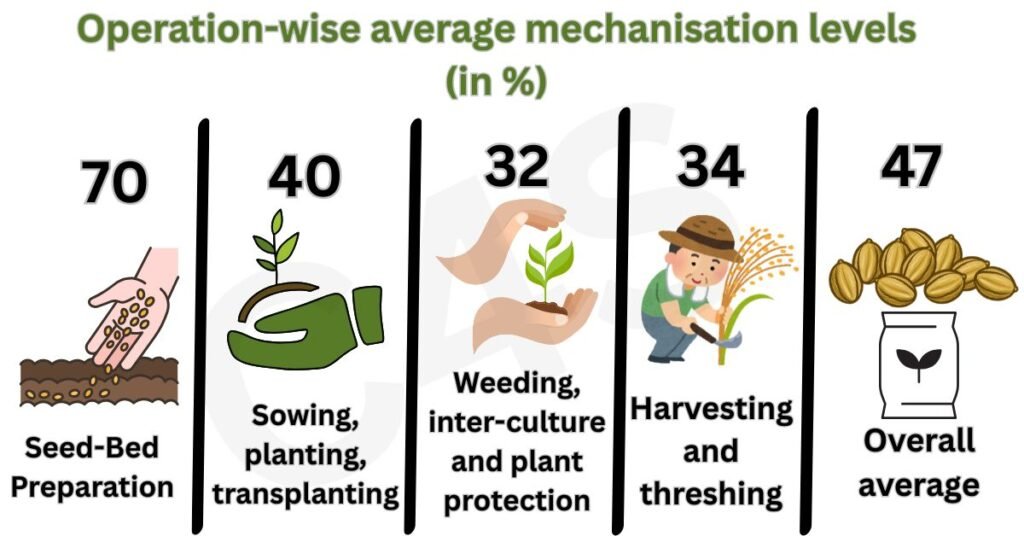

- Overall, only about 47% of farming in major crops like rice, wheat, maize, millets, pulses, oilseeds, cotton, and sugarcane is done using machines.

- Some states like Uttar Pradesh, Haryana, and Punjab have adopted farm machines quite well. But in the northeastern states, the use of machines in farming is still very low, mainly due to difficult terrain, smaller landholdings, and lack of access to equipment.

Crop-Specific Insights

- Wheat leads with 69% mechanisation, making it the most mechanised crop.

- Rice follows closely with 53% of its farming operations mechanised.

- Other crops are gradually catching up:

- Maize – 46%

- Pulses – 41%

- Oilseeds – 39%

- Cotton – 36%

- Sugarcane – 35%

- Sorghum and millets lag behind with only 33% mechanisation.

Key Areas of Mechanisation

- Seed-bed preparation is mostly done using machines (over 70%) for crops like rice and wheat. This helps make the soil just right for planting.

- Sowing and planting use machines more in wheat, but crops like sugarcane and rice still depend a lot on manual labour. On average, only about 40% of this work is mechanised.

- Weeding and inter-culture activities are less advanced, with just 32% being done by machines.

- Harvesting and threshing are only 34% mechanised overall, even though they are crucial steps in farming.

- Only rice and wheat have good mechanisation (over 60%) for harvesting, while crops like cotton are still far behind.

Global Comparisons

- United States leads with 95% farm mechanisation, supported by advanced technology, precision farming, and large-scale agricultural practices.

- Brazil stands at 75% mechanisation, using modern machinery effectively in crops like soybeans and sugarcane across vast lands.

- China has achieved 59.5% mechanisation, driven by government support and a focus on rice and wheat cultivation.

- India lags behind with 47% overall mechanisation, falling short of countries like China and Brazil.

- While India’s farm mechanisation industry is valued at around ₹9,200 crores (as of 2022), the global industry stands at approximately $100 billion. India aims to grow its share to ₹15,000 crores by 2026.

Factors at Play

- Socio-Economic Conditions:

- Farmers’ income levels and living standards affect whether they can afford and use machines on their farms.

- Geographical Factors:

- The type of land, weather, and soil in an area decides how easily machines can be used.

- Crop Diversity:

- Each crop grows differently and needs different kinds of tools and farming methods.

- Irrigation Facilities:

- The presence or absence of water sources affects how well machines can be used in farming.

Benefits of Mechanisation

- Cost Savings:

- Using machines helps farmers save about 15–20% on seeds and fertilizers.

- Improved Germination:

- Mechanised farming improves how well seeds grow, with better germination by 7–25%.

- Time Efficiency:

- Machines help farmers finish their work faster, saving 20–30% of their time.

- Small and Marginal Farmers:

- Since 86% of farmers have less than 2 hectares of land, they need smaller, affordable machines made for small farms.

Related Government Initiatives

- Sub-Mission on Agricultural Mechanisation (SMAM):

- Started in 2014-15, this government scheme helps farmers use more machines in farming. It gives money support to buy machines, set up Custom Hiring Centres (CHCs) where farmers can rent equipment, and Farm Machinery Banks (FMBs) to store and share tools.

- SMAM also includes setting up hi-tech machinery hubs, training farmers, spreading awareness, and making sure machines meet quality standards.

- Between 2014-15 and 2020-21, the government spent over ₹4,556 crore through SMAM. This helped create more than 27,500 Custom Hiring Centres and distribute over 13 lakh machines to farmers.

- Make in India:

- The government supports Indian companies to build farm machines by giving help for research, skill training, and easier rules for testing equipment.

Preference is given to Made-in-India machinery in government purchases to boost local production and support Indian manufacturers.

- The government supports Indian companies to build farm machines by giving help for research, skill training, and easier rules for testing equipment.

State-Specific Initiatives

- Rajasthan is encouraging farm mechanisation through an agri-tech mission mentioned in its state budget. This mission offers subsidies on different types of machines, especially helping small, marginal, and women farmers.

- Karnataka is planning to set up 100 Harvester Hubs and is investing in farm machines through the Krishi Bhagya scheme.

- The state is also focusing on scientific and integrated farming methods to help farmers increase their income in the long run.

Infrastructure Development

- Rural Roads and Connectivity:

- Better village roads and transport systems make it easier to move farm machines to and from fields.

- Electricity Access:

- A steady power supply is important for running electric farm machines. Using solar-powered equipment can help solve electricity problems in remote areas.

Collaboration with Private Sector

- Industry Partnerships:

- Working together with private companies, especially those that make farm machines, can help bring in new ideas and speed up the use of modern technology in farming.

- Mahindra & Mahindra is focusing on automation, like self-driving tractors, which can reduce manual work, increase efficiency, and lower costs for farmers.

- Their new OJA tractor range is packed with smart features designed to help small farmers use advanced technology.

- Start-ups and Agri-Tech Companies:

- Supporting new and growing businesses that work on farm machines and smart farming can help bring useful innovations to farmers.

Customisation for Small Landholdings

- Small and Marginal Farmers:

- Since most Indian farmers have very small farms, they need specially designed machines like mini tractors and small tools.

Sharing machines through cooperative models can also help farmers who can’t afford to buy them individually.

- Since most Indian farmers have very small farms, they need specially designed machines like mini tractors and small tools.

- Affordable Technology:

- It’s important to create low-cost machines that work well on small farms and are easy for farmers to use and maintain.

Policy Reforms

- Trade Policies:

- The government should control the import of low-quality foreign machines and at the same time support Indian manufacturers to grow and compete.

- Incentivising Research:

- Giving tax benefits and financial support to companies that invest in developing better, affordable farm equipment can encourage more innovation.

Promotion of Agri-Entrepreneurship

- Young Entrepreneurs:

- Motivating young people to start farm machinery service businesses can help build a strong support system for farmers.

- Skill Development Institutes:

- Setting up training centres to teach people how to repair and maintain farm machines can ensure farmers get help when their equipment breaks down.

Challenges

- Skills Gap:

- Many farmers don’t know how to use modern machines or manage new farming technology.

- Small Landholdings:

- Most farmers in India have very small farms, so buying costly machines isn’t practical for them.

- Rainfed Agriculture:

- About half of India’s farmland depends only on rain, so it needs special types of machines suited for uncertain water supply.

What more to be done for achieving 75-80% Farm Mechanisation in India?

- Financial Support and Incentives:

- Giving subsidies or money support helps farmers buy machines. Special focus should be on helping small and marginal farmers afford them.

- Indigenous Solutions:

- It’s important to develop machines that suit local farming needs through research and innovation.

- ‘Make in India’ Initiatives:

- Indian manufacturers should focus on building tools and machines that fit our soil, crops, and small farm sizes.

- Precision Farming Technologies:

- Using modern tools like GPS tractors, drones, and sensors can help save resources and grow more crops efficiently.

Conclusion

Farm mechanisation isn’t just about using machines instead of human hands — it’s about making farming smarter, faster, and more efficient. It helps farmers grow more food with less effort, save time, reduce costs, and deal with labour shortages. With the growing demand for food and the challenges of climate change, mechanisation ensures that farming stays productive and reliable. For small and marginal farmers, access to affordable and suitable machines can change their lives by increasing income and reducing drudgery. As India moves forward, smart and inclusive mechanisation — backed by innovation, training, and strong support systems — will be key to building a future where farming is not only profitable but also sustainable for generations to come.